Explicit FEA Cracks

FEA calculations can model explicit cracks.

Explicit Cracks

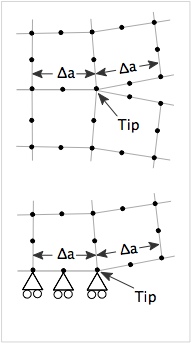

Cracks in FEA calculations are set up by configuring the mesh to include a crack. A crack can be internal to the mesh or, for symmetric loading, can be on an edge of the mesh and defined with the help of boundary conditions. These two crack geometries are illustrated on the right. In the first form, the two element edges to the right of the crack tip are initially aligned on the same coordinates. When the crack is loaded in tension, the edges separate and the point where they are joind is the crack tip. The static FEA run in NairnFEA does not include contact and therefore only opened crack can be modeled.

The second form of crack is for symmetric loading. The crack plane is on the bottom of the object and the displacement boundary conditions determine the location of the crack tip

Crack Closure Calculations

In crack closure calculations, nodal forces and displacements are used to find mode I and mode II energy release rate for crack growth. The calculations are done after the analysis is done and NairnFEAMPM is configured to do the calculations. A recent paper on crack closure calculations for a variety of elements and allowing for crack surface tractions is in Nairn (2012).[1]. This reference was the bases of the NairnFEAMPM calculations. That pointed pointed out the for the best results, the crack plane edges in front of and behind the crack tip must initially be collinear and of be of equal length (Δa).

Crack closure calculations can be done for any element type allowed in NairnFEA. In addition, one special crack tip element available and it is selected using the CrackTip command.

Crack Tip Command

References

- ↑ J.A. Nairn, "Generalized Crack Closure Analysis for Elements with Arbitrarily-Placed Side Nodes and Consistent Nodal Forces," Int. J. Fracture, 171, 11-22 (2011). (PDF version)