Difference between revisions of "Imperfect Interfaces"

| Line 52: | Line 52: | ||

The above commands set the default imperfect interface parameters for crack surfaces. When a simulation only has only one crack, this setting is enough. For simulations with more than one crack, you can set [[Defining Cracks#Crack as Imperfect Interface|different imperfect interface parameters]] for each crack, or convert some [[Friction|cracks to frictional sliding]], by using settings available when [[Defining Cracks|defining the cracks]]. | The above commands set the default imperfect interface parameters for crack surfaces. When a simulation only has only one crack, this setting is enough. For simulations with more than one crack, you can set [[Defining Cracks#Crack as Imperfect Interface|different imperfect interface parameters]] for each crack, or convert some [[Friction|cracks to frictional sliding]], by using settings available when [[Defining Cracks|defining the cracks]]. | ||

For imperfect interface modeling | For imperfect interface modeling with [[Defining Cracks|cracks]], you must use the [[Detecting Contact#ContactPosition Command|displacements method]] (''i.e.'', no <tt>ContactPosition</tt> command) because it is not possible to accurately determine displacement discontinuities from extrapolated positions (''i.e.'', when using a <tt>ContactPosition</tt> command). If this requirement cannot be met, an alternative for imperfect interface modeling using [[Multimaterial MPM|multimaterial mode]] is to use a [[Defining Cracks|crack with a traction law]] on the crack. Although traction laws can work, imperfect interface modeling is more accurate when it can be used. | ||

=== Imperfect Interfaces in Multimaterial MPM === | === Imperfect Interfaces in Multimaterial MPM === | ||

| Line 67: | Line 67: | ||

The above commands set the default imperfect interface properties for contact between any two materials. When a simulation only has two materials connected by an interface, this setting is enough. For simulations with more than two materials, you can set different interface parameters for each material pair, or even combine material pairs connected by an imperfect interfaces with those [[Friction|interacting by friction]], by using a [[Common Material Properties#Contact Properties|<tt>Contact</tt> material property]] for the secondly-defined material or each pair needing different contact mechanics. | The above commands set the default imperfect interface properties for contact between any two materials. When a simulation only has two materials connected by an interface, this setting is enough. For simulations with more than two materials, you can set different interface parameters for each material pair, or even combine material pairs connected by an imperfect interfaces with those [[Friction|interacting by friction]], by using a [[Common Material Properties#Contact Properties|<tt>Contact</tt> material property]] for the secondly-defined material or each pair needing different contact mechanics. | ||

For imperfect interface modeling in [[Multimaterial MPM|multimaterial mode]], you must use the [[Detecting Contact#ContactPosition Command|displacements method]] (''i.e.'', no <tt>ContactPosition</tt> command) because it is not possible to accurately determine displacement discontinuities from extrapolated positions (''i.e.'', when using a <tt>ContactPosition</tt> command). This limitation means the imperfect interfaces must all be in contact in the initial state. If these requirements cannot be met, an alternative to imperfect interface modeling using [[Multimaterial MPM|multimaterial mode]] is to use explicit cracks with a [[Defining Cracks|crack with a traction law]]. Although traction laws can work, imperfect interface modeling is more accurate when it can be used. | |||

=== Interfacial Energy === | === Interfacial Energy === | ||

Revision as of 10:32, 3 April 2017

Both NairnMPM and NairnFEA can model imperfect interfaces between phases in composite structures.

Imperfect Interface Theory

Modeling interfaces, which are often finite-thickness interphases, in composite materials is difficult. In numerical modeling, it would seemingly be straight-forward to discretize interphase zones and thereby explicitly model all effects. This approach has two problems. First, interphase zones may be much smaller than the bulk materials. Resolving both bulk materials and a thin interphase would require a highly refined model, which may exceed computational capacity. Second, interphase properties may be unknown and/or may vary within a transition zone from one material to another. Alternative methods for interphase modeling are needed to overcome these challenges. This need is especially important in nanocomposites because the amount of interphase per unit volume of reinforcement greatly exceeds the amount of interphase in composites with micron or larger reinforcement phases. As a consequence, interphases are expected to play a larger role, good or bad, in nanocomposite properties.

One way to model interphases is to abandon attempts for explicit modeling and instead replace 3D interphases with 2D interfaces[1] The interphase effects are reduced to modeling the response of 2D interfaces due to tractions normal and tangential to the interfacial surface, which can be modeled by interface traction laws. Elimination of 3D interphases removes the resolution problem. The use of interface traction laws also replaces numerous unknown and potentially unmeasurable interphase properties with a much smaller number of interface parameters. If interface traction laws can be determined, one can potentially model interphase effects well. Examples of using this for analytical modeling of interface effects in composite materials are in Hashin (1991)[2][3] and Nairn and Liu (1997).[4] Implementation of imperfect interfaces in FEA and in MPM is described in Nairn (2007).[5] An alternative method for modeling imperfect interfaces in MPM using multimaterial MPM is described in Nairn (2013).[6]

Imperfect Interface Traction Laws

To model 3D interphase effects using imperfect interfaces, the 2D interface is allowed to develop displacement discontinuities. For an isotropic interphase, it suffices to resolve interfacial traction into normal and tangential tractions (Tn and Tt) and assume they are functions of normal and tangential displacement discontinuities ([un] and [ut]) at the interface:

[math]\displaystyle{ T_n = f_n([u_n],[u_t]) \qquad {\rm and } \qquad T_t = f_t([u_n],[u_t]) }[/math]

Interfaces in composite materials may develop potential energy that is needed for effective property analysis.[7] For an elastic interface, interfacial potential energy is:

[math]\displaystyle{ \phi_i = \int_{S_i}\left(\int \vec T\cdot[d\vec u]\right) dS }[/math]

where Si is interfacial area.

The simplest assumption for traction laws is that they are linear and elastic. The tractions become:

[math]\displaystyle{ T_n = D_n[u_n] \qquad {\rm and } \qquad T_t = D_t[u_t] }[/math]

and interfacial energy becomes

[math]\displaystyle{ \phi_i = {1\over2} \int_{S_i} \left( D_n[u_n]^2 + D_t[u_t]^2\right) dS }[/math]

Notice that all 3D interphase properties have been reduced to just two interface parameters, Dn and Dt. These interface stiffnesses range from zero, for a debonded interface with no tractions, to infinity, for a perfect interface with no displacement discontinuity.

Imperfect Interfaces in MPM

In NairnMPM, imperfect interface can be modeled using either explicit cracks or using multimaterial mode MPM. The use of cracks works well for interfaces within a single material. The use of multimaterial mode works well for material-material interfaces in composites. The basic process is to define one or more contact law for an imperfect interface and then use the commands below to assign those laws to various contact mechanics tasks.

Imperfect Interfaces on Explicit Cracks

Explicit cracks in NairnMPM can model imperfect interface mechanics on crack surfaces. In this mode, the cracks are actually internal interfaces rather than cracks. To set up calculations where cracks are interfaces in scripted input files, use the command

ContactCracks (lawID)

In XML files, cracks as imperfect interfaces are set up with a modified <Friction> command within the <Cracks> element in the <MPMHeader>:

<Friction law='(lawnum)' lawname='(lawID)'/>

where (lawID) is the ID of the desired imperfect interface contact law. In XML files, the contact law can also be selected by is number (in (lawnum)), but if both ID and number are used in the same command, the ID is used to select the law.

The above commands set the default imperfect interface parameters for crack surfaces. When a simulation only has only one crack, this setting is enough. For simulations with more than one crack, you can set different imperfect interface parameters for each crack, or convert some cracks to frictional sliding, by using settings available when defining the cracks.

For imperfect interface modeling with cracks, you must use the displacements method (i.e., no ContactPosition command) because it is not possible to accurately determine displacement discontinuities from extrapolated positions (i.e., when using a ContactPosition command). If this requirement cannot be met, an alternative for imperfect interface modeling using multimaterial mode is to use a crack with a traction law on the crack. Although traction laws can work, imperfect interface modeling is more accurate when it can be used.

Imperfect Interfaces in Multimaterial MPM

Multimaterial mode MPM can implement imperfect interface mechanics at all nodes seeing more than one material. This type of analysis is best suited to modeling interface effects in complex 2D or 3D composite materials. To set up interface calculations in scripted MPM files, use the command

ContactMM (lawID)

[In XML files, imperfect interfaces are set up with a modified <Friction> command within the <MultimaterialMode> element:

<Friction law='(lawnum)' lawname='(lawID)'/>

where (lawID) is the ID of the desired imperfect interface contact law. In XML files, the contact law can also be selected by is number (in (lawnum)), but if both ID and number are used in the same command, the ID is used to select the law.

The above commands set the default imperfect interface properties for contact between any two materials. When a simulation only has two materials connected by an interface, this setting is enough. For simulations with more than two materials, you can set different interface parameters for each material pair, or even combine material pairs connected by an imperfect interfaces with those interacting by friction, by using a Contact material property for the secondly-defined material or each pair needing different contact mechanics.

For imperfect interface modeling in multimaterial mode, you must use the displacements method (i.e., no ContactPosition command) because it is not possible to accurately determine displacement discontinuities from extrapolated positions (i.e., when using a ContactPosition command). This limitation means the imperfect interfaces must all be in contact in the initial state. If these requirements cannot be met, an alternative to imperfect interface modeling using multimaterial mode is to use explicit cracks with a crack with a traction law. Although traction laws can work, imperfect interface modeling is more accurate when it can be used.

Interfacial Energy

When an analysis has imperfect interfaces, you can track total interface energy using global archiving methods. In an elastic analysis, the total strain energy is the sum of the strain energy and the interface energy. You should use this total energy when calculating effective composite properties by energy methods.[7]

Imperfect Interfaces in FEA

In NairnFEA, imperfect interfaces are modeling by inserting interface elements. The procedure is as follows:

- Define one or more imperfect interface materials and enter their interface parameters. Because NairnFEA is for linear elastic analysis only, the imperfect interface materials have to be linear elastic as well. In other words, the traction laws are linear with interface parameters Dn and Dt.

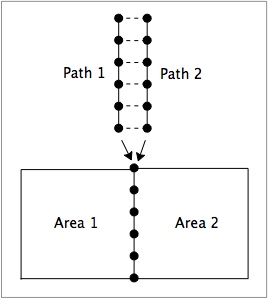

- Define two different, but overlapping paths that have the some number and arrangement of nodes. In other words, define the paths with the same number of nodes, having the same ratio of element sizes, and using keypoints that are distinct but have matching coordinates.

- Use the two paths in two areas for solid materials having the two materials to be connected by an imperfect interface. In other words, before you can create the interface elements, the paths for the interface must have each been previously used in exactly one quadrilateral area.

- Use the two paths in an area command that uses interface elements that are compatible with the type of solid elements used in the areas in step 3 (i.e., linear interface with linear elements or a quadratic interface with quadratic elements).

Interfacial Stress and Strains

Because interface elements had zero thickness, they cannot define stresses and strains. They do, however, model displacement discontinuities and have tractions. The displacement discontinuities in calculations are found from the nodal displacements. The resulting interfacial tractions are output in the element stresses. The normal traction, Tn is output in σxx while the tangential traction, Tt, is output in τxy.

Interfacial Energy

When calculating effective composite properties using energy methods,[7] it is necessary to include both strain energy and interfacial energy. When the FEA model has imperfect interface elements, their interfacial energy is output in element stain energy. The total energy from all elements is the sum of strain energy an interfacial energy. You should use this total energy when calculating effective composite properties by energy methods.[7]

Deprecated Imperfect Interface Commands in MPM

Contact laws were implemented in NairnMPM (January 2016) and OSParticulas (revision 695). Prior to this new feature, imperfect interfaces were limited to simple linear laws and the interface parameters were entered differently. This section documents the deprecated commands. They still work, but command files should be convert to the new methods documented above.

Imperfect Interfaces on Explicit Cracks (Deprecated)

Explicit cracks in NairnMPM can model imperfect interface mechanics on crack surfaces. In this mode, the cracks are actually internal interfaces rather than cracks. To set up calculations where cracks are interfaces

In scripted input files, imperfect interface mechanics on crack surfaces was set using the command

ImperfectInterface (Dt),(Dntens),(Dncomp)

In XML files, cracks as imperfect interfaces were set up with a modified <Friction> command within the <Cracks> element in the <MPMHeader>:

<Friction Dt="(Dt)" Dn="(Dntens)" Dnc="(Dncomp)">11</Friction>

The parameters are described below.

Imperfect Interfaces in Multimaterial MPM (Deprecated)

In scripted MPM files, mplement imperfect interface mechanics at all nodes seeing more than one material was set using the command

ImperfectInterfaceMM (Dt),(Dntens),<(Dncomp)>

In XML files, imperfect interfaces were set up with a modified <Friction> command within the <MultimaterialMode> element:

<Friction Dt="(Dt)" Dn="(Dntens)" Dnc="(Dncomp)">11</Friction>

where

- (Dt) is the imperfect interface parameter in the tangential direction (in pressure/length units)

- (Dntens),(Dncomp) are the imperfect interface parameters for the normal direction (in pressurelength units). The use of two parameters allows modeling of non-linear interfaces that have different stiffness in the tensile and compressive directions. In other words, (Dntens) is the interface parameter when the surface are separated and therefore in tension. (Dncomp) is the interface parameter with the surfaces are in contact and therefore in compression. If only (Dntens) is specified (which can also use a Dnt attribute), the interface will be linear and have the same stiffness in tension and compression.

In XML files, the value of of the <Friction> element should be greater than 10 as a flag to indicate material contact is modeled as an interface rather than frictional contact.

In theory, the interface becomes perfect in either direction as the interface parameters approach infinity, but high values for stiffness make the problem numerically unstable (unless very small time steps are used). To make the interface perfect in any direction, set the stiffness to -1, instead of using a high stiffness. A common situation is to model the interface as perfect in compression but imperfect in tension. Such an interface can be created by setting (Dntens) to a stiffness value and (Dncomp)=-1.

The above commands set the default imperfect interface parameters for contact between any two materials. Custom imperfect interfaces (or conversion to interacting by friction) was done using a Friction or Interface material property for the secondly-defined material of each pair needing different contact mechanics.

References

- ↑ Z. Hashin, "Thermoelastic properties of fiber composites with imperfect interface," Mech. of Materials, 8, 333–348 (1990).

- ↑ Z. Hashin, "Composite materials with viscoelastic interphase: Creep and relaxation," Mech. of Materials, 11, 135–148 (1991).

- ↑ Z. Hashin, "Thermoelastic properties of particulate composites with imperfect interface," Journalof the Mechanics and Physics of Solids, 39, 745–762 (1991).

- ↑ J. A. Nairn and Y. C. Liu, "Stress transfer into a fragmented, anisotropic fiber through an imperfect interface," Int. J. Solids Structures, 34, 1255–1281 (1997).

- ↑ J. A. Nairn, "Numerical implementation of imperfect interfaces," Computational Materials Science, 40, 525–536 (2007).

- ↑ J.A. Nairn, "Modeling Imperfect Interfaces in the Material Point Method using Multimaterial Methods," Computer Modeling in Eng. & Sci., 92, 271-299 (2013).

- ↑ 7.0 7.1 7.2 7.3 Z. Hashin, "Extremum principles for elastic heterogenous media with imperfect interfaces and their application to bounding of effective moduli." Journal of the Mechanics and Physics of Solids, 40, 767–781 (1992).