Difference between revisions of "Isotropic Material Failure Surface"

| Line 6: | Line 6: | ||

== Failure Surface == | == Failure Surface == | ||

[[File: | [[File:MaxPrinciple.png|400px|right]] | ||

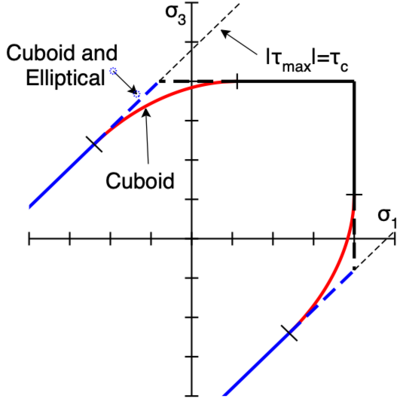

Three possible failure stress failure surfaces are shown in the figure. The surface along each axis gives the current strength by that stress. The current strength may depended on external variables such as pressure, strain rate in more. During damage evolution, the current strength will also depend on current damage state. Which failure surface to use for initiation and subseqent damage evolution is determined by the <tt>tractionFailureSurface</tt> property of the parent [[Isotropic Softening Material|isotropic softening material]]. The calculations for current strength transpose these surfaces to principle stress space and find critical stress by Mohr's circle calculations. The details are given in Ref. <ref name="dmGen"/>. | Three possible failure stress failure surfaces are shown in the figure. The surface along each axis gives the current strength by that stress. The current strength may depended on external variables such as pressure, strain rate in more. During damage evolution, the current strength will also depend on current damage state. Which failure surface to use for initiation and subseqent damage evolution is determined by the <tt>tractionFailureSurface</tt> property of the parent [[Isotropic Softening Material|isotropic softening material]]. The calculations for current strength transpose these surfaces to principle stress space and find critical stress by Mohr's circle calculations. The details are given in Ref. <ref name="dmGen"/>. | ||

Revision as of 11:24, 17 November 2023

Introduction

This damage initiation law predicts that failure initiates when maximum principal stress exceeds tensile strength of the material or when maximum shear stress exceeds shear strength of the material. It can also model pressure-dependent initiation stresses. Because it deals with principal stresses and tensile failure is the same regardless of direction, this law is only appropriate for isotropic materials such as an IsoSoftening material.

Failure Surface

Three possible failure stress failure surfaces are shown in the figure. The surface along each axis gives the current strength by that stress. The current strength may depended on external variables such as pressure, strain rate in more. During damage evolution, the current strength will also depend on current damage state. Which failure surface to use for initiation and subseqent damage evolution is determined by the tractionFailureSurface property of the parent isotropic softening material. The calculations for current strength transpose these surfaces to principle stress space and find critical stress by Mohr's circle calculations. The details are given in Ref. [1].

Pressure Dependent Shear Strength

Although generalized damage mechanics[1] provides a method to allow the failure surface to depend on any external variable, the only external dependence currently modeled is to allow shear strength to depend on pressure.

Model 0: shear strength is independent of pressure

Model 1: shear strength is linear in pressure:

[math]\displaystyle{ \tau = \tau_c\left(1 + {P\over \tau_h}\right) }[/math]

where [math]\displaystyle{ \tau_h }[/math] is hydrostatic tension that causess shear strength to reach zero under hydrostatic tension when [math]\displaystyle{ P=-\tau_h }[/math]. Note with out pressure dependence, a material never failures by shear strength in hydrostatic stress states. Furthermore, [math]\displaystyle{ \tau_h }[/math] must be higher the normal strength [math]\displaystyle{ \sigma_c }[/math].

Model 2: shear strength is step linear. The shear strength below [math]\displaystyle{ P_1 }[/math] is equal to basic shear strength, [math]\displaystyle{ \tau_c }[/math], but for [math]\displaystyle{ P\gt P_1 }[/math], it increases linearly to [math]\displaystyle{ \tau_{max} }[/math] at [math]\displaystyle{ P_2 }[/math]. Above [math]\displaystyle{ P_2 }[/math], the shear strength is constant and equal to [math]\displaystyle{ \tau_{max} }[/math]. For [math]\displaystyle{ P\gt P_1 }[/math], the shear strength is

[math]\displaystyle{ \tau = \tau_c + {\tau_{max}-\tau_c \over P_2-P_1}\bigl(\min(P,P_2)-P_1\bigr) }[/math]

Model 3: shear stength is exponential with an asymptote. The shear strength below [math]\displaystyle{ P_1 }[/math] is equal to basic shear strength, [math]\displaystyle{ \tau_c }[/math], but for [math]\displaystyle{ P\gt P_1 }[/math], it increases exponentially and asymptotically to [math]\displaystyle{ \tau_{max} }[/math]. For [math]\displaystyle{ P\gt P_1 }[/math], the shear strength is

[math]\displaystyle{ \tau = \tau_c + (\tau_{max}-\tau_c)\left(1-\exp\left(-{\ln 2 (P-P_1)\over P_2}\right)\right) }[/math]

Note that [math]\displaystyle{ P_2 }[/math] (which must be > 0) is the pressure increment above [math]\displaystyle{ P_1 }[/math] required for the shear strength to be half way between [math]\displaystyle{ \tau_c }[/math] and [math]\displaystyle{ \tau_{max} }[/math].

Model 4: shear stength is sigmoidal exponential. The shear strength evolves from [math]\displaystyle{ \tau_c }[/math] to [math]\displaystyle{ \tau_{max} }[/math] using a sigmoidal shape that is half way to [math]\displaystyle{ \tau_{max} }[/math] at [math]\displaystyle{ P_1 }[/math] and 1/3 or 2/3 of the way there as [math]\displaystyle{ P_1\mp P_2 }[/math]. For all [math]\displaystyle{ P }[/math], the shear strength is

[math]\displaystyle{ \tau = \tau_c + {(\tau_{max}-\tau_c)\over 1+\exp\left(-{\ln 2 (P-P_1)\over P_1}\right)} }[/math]

Some pressure-dependent examples suggest this model is the most stable.

A complication when using pressure dependence properties is the stability of damage mechanics depends on the strength properties. To allow this calculation at the beginning of the calculations the simulations should set maxPressure property to the maximum pressure expected during the simulation.

Damage Law Properties

The following table lists the input properties for maximum principal stress failure surface:

| Property | Description | Units | Default |

|---|---|---|---|

| sigmac | Critical tensile stress for failure | pressure units | infinite |

| tauc | Critical shear stress for failure | pressure units | infinite |

| PressureModel | Pick a model (0 to 4) to model pressure dependent shear strength | none | 0 |

| tauh | Hydrostatic tension that causes shear strength to drop to zero for pressure model 1 or maximum shear strength for pressure models 2, 3, and 4 | pressure units | infinite |

| P1 P2 |

Break points for shear strength in pressure models 2, 3, and 4 | pressure units | 0 for P1 |

| maxPressure | The maximum pressure expected in a simulations. It is used to verify damage mechanics stability at the start of the simulation. | pressure units | 0 |